Products > Milling technology > Tapered End Mills

Tapered solid carbide die-sinking end mills are suited for use in nearly all material groups. These tools are available in the diameter area D =2 to 12mm and with angles from 0,5° – 8° and cover nearly all machining tasks in the mould- and die industry. NC- deburring tools with a cone angle of 60° or 90° cover the solutions for the requirements in deburring operations.

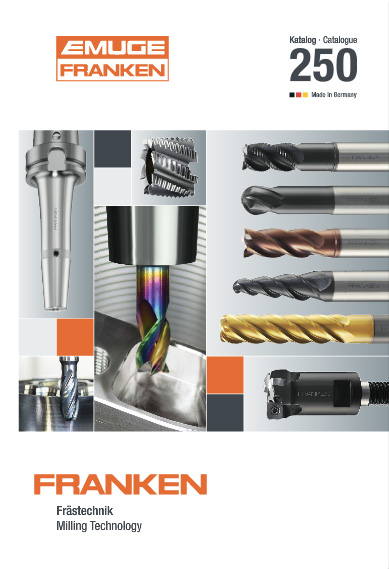

Catalogue

Demo

A demonstration of FRANKEN end mills in P20 tool steel using traditional and updated milling strategies. Finishing a surface with a standard ball end mill strategy and the new FRANKEN Circle Segment strategy, showing a 90% cycle time decrease with an improved finish. Roughing a pocket with the standard Multi-Cut roughing strategy & a new Jet-Cut Trochoidal strategy with chip breaker. The Jet-Cut Trochoidal is used to finish both pockets. Roughing a pocket with a Top-Cut VAR with & without radial chip thinning.